Date:2022-12-13 Click:857次

Date:2022-12-13 Click:682次

Date:2022-12-13 Click:561次

Date:2022-12-13 Click:831次

Date:2022-12-13 Click:548次

Date:2022-12-13 Click:822次

Date:2022-12-13 Click:562次

Date:2022-12-13 Click:929次

Date:2022-12-13 Click:726次

Date:2022-12-13 Click:925次

Date:2022-12-13 Click:999次

Date:2022-12-13 Click:775次

Date:2022-12-13 Click:850次

Date:2022-12-13 Click:893次

Date:2022-12-13 Click:652次

Environment-friendly dry-type transformers are designed to reduce environmental impact and improve safety and efficiency in electrical power distribution. Here are some key aspects of their working conditions:

1. Cooling System: Dry-type transformers use air for cooling instead of oil. They often incorporate advanced cooling technologies like forced air or natural air circulation to maintain optimal operating temperatures.

2. Insulation: These transformers use solid insulation materials such as epoxy resin, which are non-toxic and non-flammable. This reduces the risk of fire and environmental contamination.

3. Noise Levels: Dry-type transformers generally operate with lower noise levels compared to their oil-filled counterparts. This makes them suitable for indoor installations in residential, commercial, and industrial buildings.

4. Maintenance: They require less maintenance since there is no risk of oil leakage. Regular inspections for dust and debris accumulation are necessary to ensure efficient cooling and operation.

5. Efficiency: High-efficiency designs minimize energy losses, leading to reduced operational costs and environmental impact. Energy-efficient transformers contribute to lower greenhouse gas emissions.

6. Installation: They are versatile and can be installed indoors or outdoors without the need for special fire-resistant barriers or containment areas.

7. Safety: The absence of flammable oil makes dry-type transformers safer, reducing the risk of fires and explosions. This makes them ideal for use in environments where fire safety is a critical concern.

8. Environmental Impact: By eliminating the use of oil, dry-type transformers reduce the potential for soil and water contamination. Their solid insulation materials are also more environmentally friendly.

9. Standards and Regulations: They are designed and manufactured to meet stringent environmental and safety standards, such as those set by organizations like the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL).

10. Applications: Suitable for a wide range of applications, including commercial buildings, hospitals, data centers, renewable energy installations, and other critical infrastructure where reliability and environmental considerations are paramount.

These conditions and features make environment-friendly dry-type transformers a sustainable and safe choice for modern electrical power distribution needs.

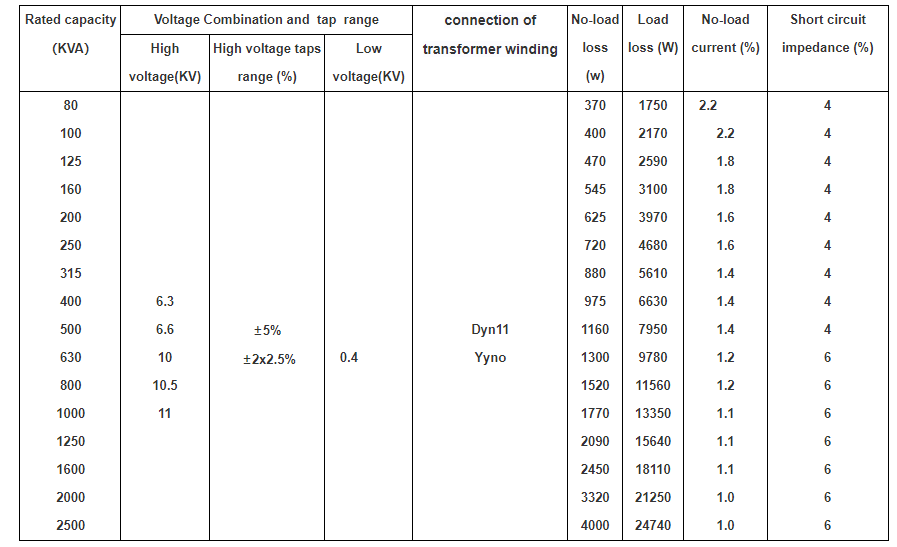

The technique parameter